categorias

- Notícia (6)

Em jato de tinta industrial, Tintas UV e algumas de suas limitações, jato de tinta à base de água está desfrutando de um renascimento. Quando se trata das aplicações mais exigentes, é um desafio para as tintas à base de água atingir o desempenho de resistência necessário sem o risco a longo prazo de bloquear o cabeçote. É aqui que a tinta mista oferece uma solução potencial.

O que significa híbrido?

O termo “blend” is commonly used when inks are not easily classified by the traditional “platform” categories of UV, oil, water-based or hot melt adhesive, often in cases where the formula designer deliberately combines the two techniques. The goal is to combine the best of each approach to solve a particular problem. Consider the Centauri cavalry of Greek mythology, which combined the speed of a horse with the fighting instinct of a human, rather than a cavalry.

The metaphorical rider’s printing equivalent is one that requires the application of two techniques to solve a problem, such as the use of flexo printing UV varnish to cover the water-based inkjet inks used for label printing. In some cases, this may be the best approach, especially if the printer design allows it, but when a single layer is required, combining the functions of both fluids into a single product can be beneficial.

Water-borne ultraviolet light

Probably the most common blending method is water-based UV ink, or AQ-UV. Aq-uv inks, although not conceptually unfamiliar, have been disclosed in patents since the early 2000s, but have been the subject of considerable intensive research over the past 10 years. This is most likely due to a large number of print heads damaged by early prototype inks containing conventional self-crosslinking resins. Today, companies such as Konica Minolta, Sun Chemical, Agfa, Fujifilm, Tiger Coatings and EFI hold patents on everything from textiles and packaging to metal finishes.

The greatest advantage of AQ-UV ink is that the “solid” content of the curable component is now greatly reduced, and the final curable ink film is thus thinner. As a function of coverage, the sheen of the print looks more even, especially for dark colors. Labeling can also be better, although this is sensitive to the precise chemistry used.

The problem is that many of the materials commonly used to make UV inks are simply insoluble in water. This applies to most UV monomers and almost all photoinitiators. Thus, from an ink preparation point of view, the simplest approach is to select from a smaller list of soluble materials and simply mix them together to make ink. The problem is that if the film is not fully cross-linked, the water resistance of the resulting film will be sacrificed by this solubility, thus partially losing the expected benefit of the UV portion of the mixture.

As a result, the most common and successful successful methods tend to use reactive polymers such as “acrylic polyurethane” as resin dispersions, sometimes in combination with emulsions of photoinitiators and possibly small amounts of soluble monomers.

The meaning of craft and design

In most cases, the reactive material solidifies only after the water is dried, allowing the polymer particles to become close enough to react. This means that drying/curing is a two-step process and the printer design needs to be tailored to the characteristics of each ink.

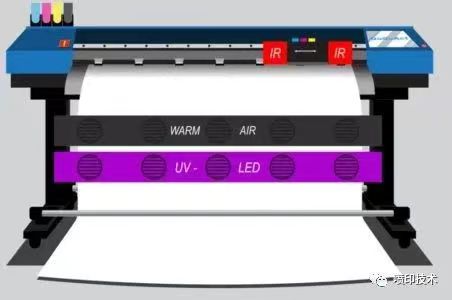

In scanning applications, the infrared dryer can be placed on the headframe, thus replacing the standard lamp in the UV printer, as in the large HP latex printer. Low power curing rods can be installed in the substrate feed direction. This is graphically shown in the figure below, which is how the Mimaki printer works using solvent UV.

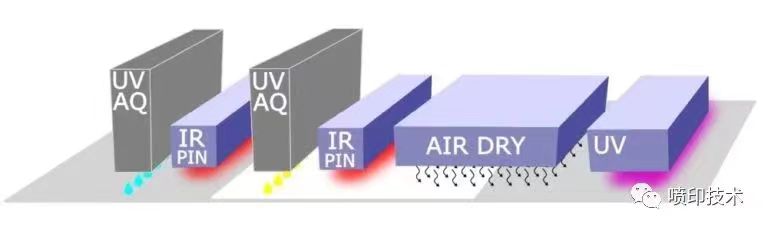

This again limits the number of water-soluble photoinitiators suitable for low-intensity LED light sources, so if a higher intensity mercury lamp source is required, a second carrier may also be considered for UV curing. The design could end up looking a bit like a Canon Colorado printer, using two scanning rails, one with head/IR and the other with UV lamp.

In a single pass printer, more space is inevitably required to ensure dryness, and it is well known that this will depend on the substrate/temperature. However, because the final UV cure will be instantaneous, it can be placed before the substrate merges and therefore does not necessarily increase the coverage area. The diagram below illustrates how different scenarios for pinning and drying can be envisaged.

Other UV mixing examples

We just mentioned the solvent UV, which has been patented by Fujifilm/Sericol. In this case, a curable polymer replaces a binder resin that would otherwise be a fairly standard solvent-based ink for large-format graphics. As a result, end-use performance, especially fastness to water, can be extended. INX also has a patent application for solvent-based UV, in this case, for printing aluminum cans.

Another frequently occurring UV hybrid is Hotmelt-UV. We have not published hot melt inks in detail since we mentioned them in our production inkjet series, but these phase change inks (sometimes called “solid inks”) have found a niche as etch masks in manufacturing applications (such as solar cells). Their main limitation, however, is that the relatively low melting point waxes of these ink types tend to result in limited etching times when exposed to pesky etching chemicals.

By adding UV-curable materials to the formulation, the resistance of wax-based inks can be greatly improved, and with the right choice of materials, ink can still be removed with industry-standard alkaline developers.

While the gel ink in the Colorado printer mentioned above is itself somewhat like a hot-melt UV, it is not wax that turns solid at room temperature, but rather causes a significant increase in viscosity.

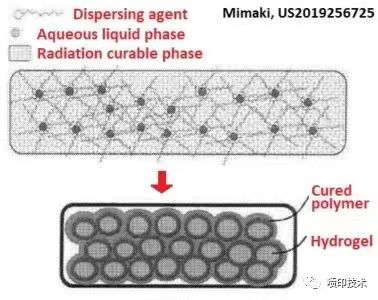

A number of other particularly interesting hybrid inks have been proposed for 3D printing applications, the most fascinating encountered by the authors was an aqueous emulsion in a UV matrix that forms a hydrogel after curing to simulate human tissue for medical training, as shown in the patent drawing below.

Beyond ultraviolet light

As discussed in our previous article, some of the same techniques have been proposed for water-based UV to cure electron beams. In this case, the rationale is similar: to eliminate the possibility of migration of harmful photoinitiators. Such techniques have been used in flexographic printing, so there are precedents, but ink-jet inks are much less viscous, so the ink is far less likely to bleed when printing wet-to-wet. Sun Chemical proposed to overcome such problems in unmixed UV inks by using small amounts of less harmful initiators. Perhaps “AQ-EB/UV” ink could also be used?

So is hybrid the best of both worlds? Well, not always due to water-soluble challenges, for example, but it can certainly enable some unique applications!